Introduction

For growing and established brands, packaging is no longer a tactical requirement—it is a strategic asset. The packaging box manufacturer you choose directly influences brand perception, operational stability, cost efficiency, and scalability.

While price often dominates initial discussions, experienced brands evaluate packaging partners through a much broader lens. Long-term growth depends on manufacturing discipline, material expertise, process reliability, and the ability to scale without compromising quality.

This guide outlines how brands should evaluate a packaging box manufacturer from a long-term, risk-aware, and growth-oriented perspective.

Manufacturing Ownership vs. Trading Dependency: Why It Matters More Than You Think

One of the first distinctions brands must understand is whether a supplier is a manufacturer or a trader coordinating outsourced production.

Manufacturers with in-house facilities maintain direct control over:

Production scheduling

Process accuracy

Quality intervention

Delivery commitments

In contrast, dependency on multiple third-party units increases variability and risk, particularly for premium packaging.

A reliable packaging box manufacturer operates with defined workflows, trained personnel, and controlled machinery, ensuring consistency across repeat orders.

Infrastructure & Machinery: The Backbone of Consistent Packaging Quality

Packaging quality is a function of infrastructure, not intention. Modern packaging manufacturers invest in advanced machinery to reduce manual error and increase repeatability.

High-quality infrastructure enables:

Accurate die-cutting for dimensional precision

Uniform pasting and alignment

Consistent finishing across large volumes

Reduced dependency on individual labor variability

Manufacturers equipped with modern German or equivalent machinery are better positioned to handle high-value, bulk, and time-sensitive packaging requirements.

Material Intelligence: Where Most Packaging Failures Begin

Material selection is one of the most underestimated aspects of packaging manufacturing. A professional packaging box manufacturer evaluates materials based on application, logistics stress, and brand positioning, not just cost.

Key considerations include:

Board thickness calibration for rigidity

Wrapping paper GSM behavior under adhesive

Moisture resistance and shelf durability

Compatibility between materials and finishes

Packaging failures—such as warping, edge lifting, or deformation—often originate from incorrect material combinations rather than manufacturing defects.

Process Discipline & Quality Control Systems

Quality in packaging manufacturing is not achieved at the final stage—it is built through process discipline.

Leading packaging box manufacturers implement multi-stage quality checks that include:

Raw material verification

Print and color accuracy control

Pasting and alignment inspection

Final visual and strength testing

This systematic approach minimizes rejections, ensures batch consistency, and protects brand reputation.

Industry-Specific Packaging Experience: One Size Does Not Fit All

Different industries demand different packaging outcomes. A manufacturer’s ability to adapt design, materials, and finishes to industry needs is a strong indicator of expertise.

For example:

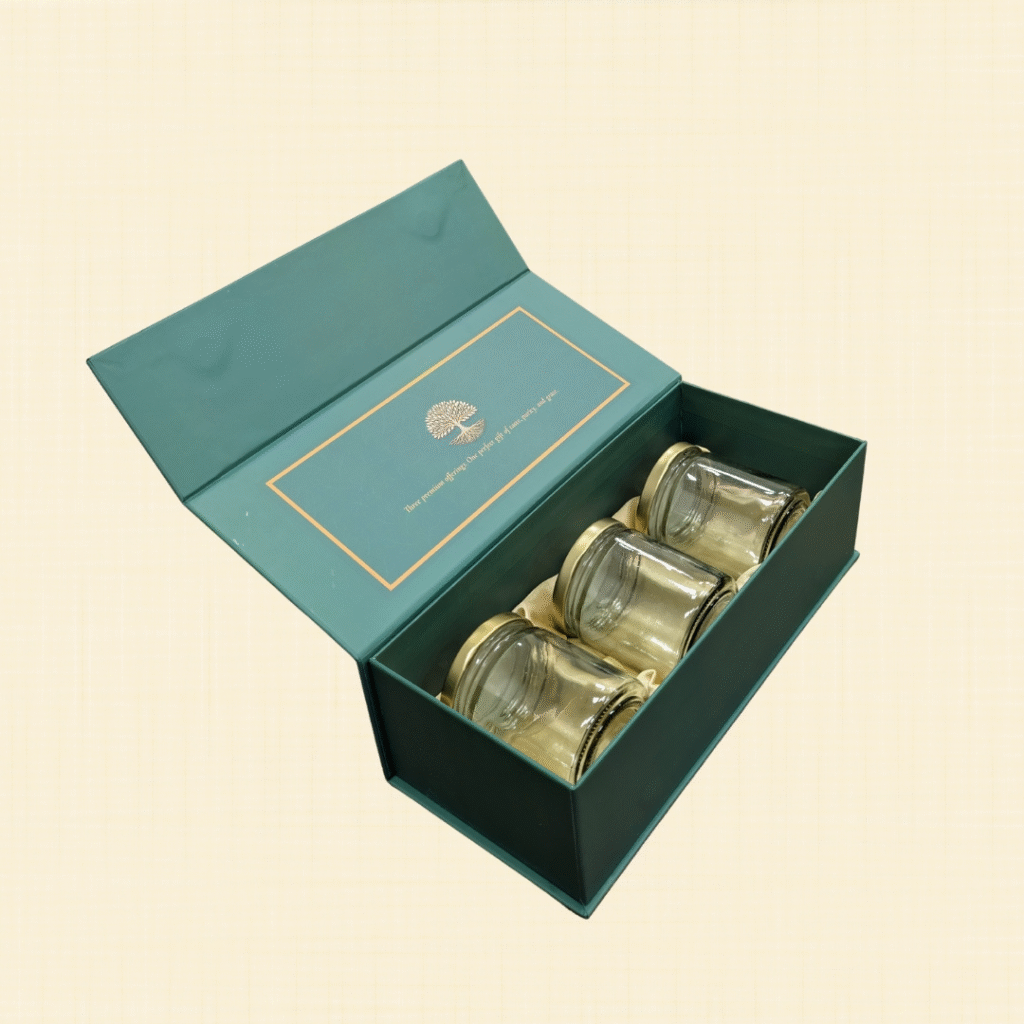

Cosmetics: Focus on shelf appeal, premium finishes, and inserts

Electronics: Emphasis on strength, cushioning, and transit protection

Corporate Gifting: Consistency, luxury presentation, and brand alignment

E-commerce: Balance between cost efficiency and durability

Manufacturers with diverse industry exposure offer tailored solutions rather than standard templates.

Choosing a Packaging Manufacturer Is an Investment in Brand Stability

The best packaging box manufacturer is not defined by price alone, but by process reliability, material expertise, infrastructure strength, and long-term alignment.

Brands that choose manufacturing-driven partners reduce operational risk, protect brand equity, and create a scalable foundation for growth.

For brands seeking a reliable, premium, and experienced packaging box manufacturer, partnering with a company that understands manufacturing at a foundational level is critical.